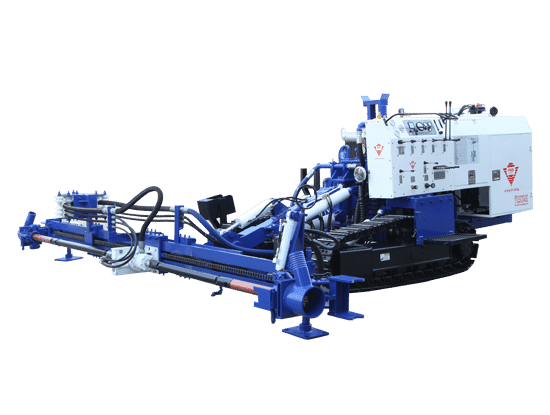

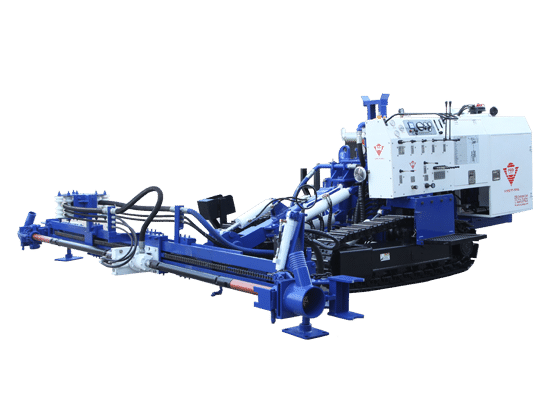

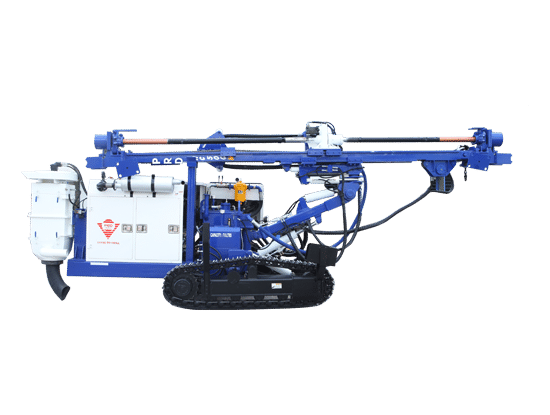

Blast Hole Rigs

MOQ : 1 Unit

Blast Hole Rigs Specification

- Condition

- New

- Product Type

- Blast Hole Rigs

- Material

- MS

- Computerized

- No

- Automatic Grade

- Automatic

- Color

- Blue And Black

Blast Hole Rigs Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Blast Hole Rigs

A PRD Drill Max HC 500 M maintains high level of productivity even under the toughest conditions Advanced Hydraulics for boom and feed positioning, Rotation, feed and tramming ensures superior performance.

| PRD HC Drill Max 500 Rig - TECHNICAL SPECIFICATIONS | |

| CAPACITY | -NA- |

| PRIME MOVER | Power for the Hydraulic is taken from the Suitable Deck Engine |

| WORK METHOD | -NA- |

| MAST | -NA- |

| PULL UP AND PULL DOWN | Max pull up force - 1500 kg Max pull down force - 1500 kg |

| GROUND CLEARANCE | -NA- |

| ROTARY HEAD | Rotary head is powered by one hydraulic motor Max torque - 1765Nm Tramming speed - 0-50 rpm |

| OPTIONAL ATTACHMENT | -NA- |

| COMPRESSOR | 400-200(separate skid) |

Precision Engineering for Tough Applications

Built from high-quality mild steel, our Blast Hole Rigs are designed to operate flawlessly in rugged conditions. The automatic features boost productivity, making them ideal for tasks requiring speed and consistency, such as mining and major infrastructure projects. Each unit passes stringent quality checks before dispatch.

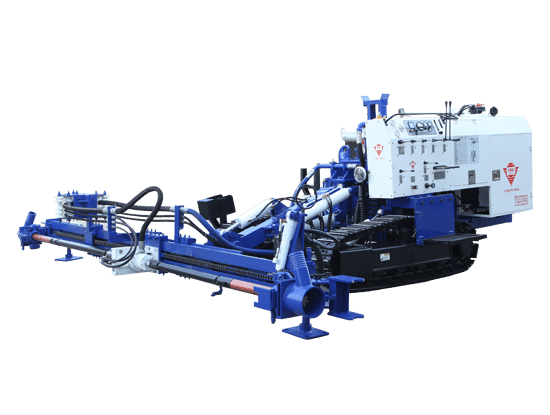

Trusted Manufacturer and Exporter from India

We are a prominent manufacturer, exporter, and supplier of Blast Hole Rigs, dedicated to providing high-performance equipment crafted in India. Our focus on reliability and customer satisfaction has made us a preferred choice for clients globally. Partner with us for robust drilling solutions tailored to your needs.

FAQs of Blast Hole Rigs:

Q: How are Blast Hole Rigs used in mining and construction projects?

A: Blast Hole Rigs are primarily used to drill precise holes into rock or earth, preparing sites for blasting operations in mining, quarrying, and large-scale construction projects. Their automatic mechanism aids productivity and efficiency on-site.Q: What materials are used in the construction of these blast hole rigs?

A: These rigs are constructed from high-grade mild steel (MS), which offers excellent strength and durability, making them suitable for heavy-duty drilling in challenging work environments.Q: When is it beneficial to use an automatic blast hole rig rather than a manual one?

A: Automatic blast hole rigs are best employed when efficiency, speed, and consistent hole quality are critical. They minimize manual intervention, reduce operational fatigue, and help maintain accuracy in continuous or large-scale drilling applications.Q: Where can I source these blue and black blast hole rigs in India?

A: You can source these rigs directly from our manufacturing facilities in India. We are a recognized manufacturer, exporter, and supplier, providing equipment both domestically and internationally.Q: What is the process for exporting these rigs outside India?

A: We manage end-to-end export formalities, including product packaging, documentation, and compliance with international standards, ensuring a seamless shipment process for clients worldwide.Q: How does the non-computerized design benefit users in remote or challenging locations?

A: The absence of computerized components simplifies maintenance and repairs, which is especially advantageous in remote areas where technical support may be limited. This design ensures continued operation and reliability.Q: What advantages do customers gain by purchasing a new, automatic-grade blast hole rig?

A: Customers benefit from advanced automation, reduced manual workload, and greater drilling consistency. Additionally, acquiring a brand new rig guarantees the latest manufacturing standards and reliability from the outset.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Geo Technical Rigs Category

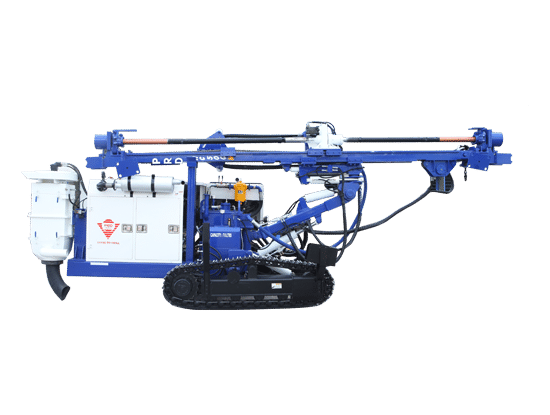

PRD 650 Blast Hole Rigs

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Condition : New

Color : Yellow

Material : MS

Product Type : Hole Rigs

PRD EX65

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Condition : New

Color : Orange

Material : MS

Product Type : Drilling Rigs

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS